When faced with a new chemical injection application for an industrial, municipal, or commercial process, often times the planning around procuring and installing all the components you need becomes a cumbersome and time consuming event. There are so many accessories you can add to a chemical metering pump to help with performance, and plenty of brands and suppliers for each part as well.

Your chemical injection application is an integral part of your business, whether it is treating a process liquid, or creating a product, the chemical pumping system(s) is likely going to run for thousands of hours for the foreseeable future. Running and continuously replenishing the system(s) will be costly and it will require training and man power to maintain optimal performance over the years to come, and this is likely where most of your stress lies, and should lie.

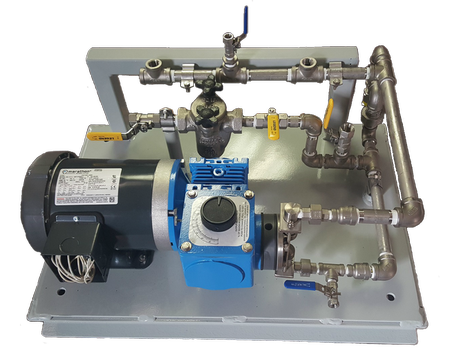

Madden Pump now offers simple, rugged, complete chemical injection skid packages, eliminating the need to search for all the pumping accessories you need, and more importantly, eliminating the time and money spent installing all of these parts and piping at your plant.

Packaged chemical dosing systems

Most chemical applications are going to use a positive displacement type pump, like a metering pump. Madden Pump makes one of the most durable, heavy duty metering pumps available on the market; and we’ve started making our full packaged dosing systems with the same simple durability in mind.

The following is a list of common accessory equipment needed for diaphragm type chemical metering pumps and a brief reason as to why:

- Back pressure valves: diaphragm metering pumps often use check ball valves at the suction and discharge ends of the pump to insure consistent and accurate output with each stroke. If your system is pumping into something with atmosphere pressure, process liquid may siphon through too easily, and the check ball valves may not seat firmly with each stroke. This significantly hurts consistent and repeatable output.

- Pulsation dampeners: positive displacement diaphragm metering pumps pump with a pulse. The flow and pressure spike with each stroke. Pulsation dampeners even out the spikes to a consistent pressure, significantly reducing the wear and tear on your system’s piping.

- Pressure Relief valves: no matter how careful you are, piping issues, accidents, and plugs can happen. A pressure relief valves ensures your chemical dosing pump will never dead head and potentially be ruined.

- Y-strainer: Y-strainers or basket strainers are great ways to ensure the particles and natural sediment found in most chemical and other process liquids, do not end up clogging your pump or pipes, and also ensures the system you are dosing into will not be contaminated.

- Pressure Gauge: ensure your chemical dosing pump and all the components are working properly with a simple gauge.

There are many other accessories Madden often includes on the packaged chemical injection skids like leak detecting pressure switches, calibration columns, flow indicators, and more. If you have anything else you need added to your chemical metering system just let us, or the Madden distributor you are working with know.

Packaged chemical dosing skids save head aches and stress

So putting this all together, pun intended, equates to cost savings and time savings. Not only are we trying to eliminate the need to install the components in your system yourself or

So putting this all together, pun intended, equates to cost savings and time savings. Not only are we trying to eliminate the need to install the components in your system yourself or

If you’ve ever personally ordered parts for a system you did not intimately have knowledge with, you know how mentally stressing this task can be. Find

ing the right pump, and each individual accessory equipment needed for your chemical injection application takes a lot of research and unfortunately, sometimes trial and error. Trust the experts at Madden Pump, or our reps, to get you squared away. Our 65 years of experience building and selling chemical metering pumps and equipment allows us to listen to what you are hoping to accomplish, and then recommending the best components for it.

Your customized chemical dosing system can come to your facility, mounted and installed on a steel skid. Everything will be piped together, and factory tested for any leaks or other issues.

All you’d have to do is find the best spot to put it, connect your chemical/process liquid to the suction end, and connect piping or a hose to the discharge end of your chemical injection

point in the process, and you’re ready to go.

No cost on installing piping and ancillary equipment, and no time spent doing so. Everything ready to go.

Conclusion

If you have a new chemical injection application at your facility, or need to replace a worn out system, consider getting everything you need conveniently on one compact skid.

Madden Pump takes pride in offering some of the most durable systems on the market that are simple and straight forward to use. Our focus is on keeping you up and running, with little to no downtime spent on maintenance or repairs, and now, to get you a full system with as little stress as possible.

Call us or shoot us an email, or get ahold of one of our local distributors near you to learn what can be put together for your next chemical dosing project.