What’s New for Madden in 2016?

Madden Pump has been making quality boiler blowdown equipment and chemical metering pumps for over 60 years. And since then, many competing companies have come and gone in the industry; some becoming part of huge conglomerates, buying up many different types of manufacturers, and others were bought to become a vital cog in another business’s repertoire.

Madden is still a family owned business in Elkhart, IN continuing to manufacture one of the best U.S. made diaphragm metering pumps for chemical injection processes as well as boiler blowdown equipment. We pride ourselves in responsive customer service and our products are virtually the same now as they were 60 years ago; but we want to continue to serve our niche market the best we can and that requires some advancements.

So here we go!

As a company we are proud to boast some new things coming from Madden in 2016. We are working on a brand new product for the farming industry as well as finding and mastering accessory products to our pumps in order to start offering completely automated pumping systems. And the completely overhauled Madden website is weeks away from being unveiled!

We’ll send out another blog on what you can expect from the new website closer to when it is ready to go live, and next week we’ll have a detailed blog on the Madden Milk Cooler™. This week we’re diving into what we’re affectionately calling Madden CAPS™.

Madden CAPS™

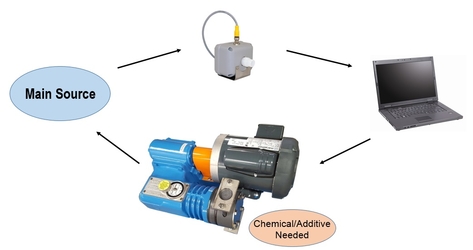

Madden CAPS™ (completely automated pumping systems) is not necessarily a new product but our combination of our pumps, a PLC, and other related accessories. The idea stemmed from several inquiries last year asking for three basic components: a paddle wheel sensor (component to read flow rate of a main liquid source), a PLC (to read the flow rate and send an appropriate frequency to the VFD controller), and one of our Madden chemical metering pumps with a VFD controlled motor and 4-20 mA signal follower. It seems that the demand was stemming from applications that previously used smaller, solenoid driven pumps (as opposed to a motor driven pump). Solenoid driven pumps have their place and are a cost effective solution for dosing into a process various times throughout a work day. However, their longevity may be questionable when the application requires constant dosing, closer to 24/7/365.