You would think with a positive displacement pump the manufacturer would want to make the driving force of the liquid as strong as possible, right? And for a diaphragm type  chemical metering pump, this would be the diaphragm. According to our distributors across the country, our competitors’ diaphragms are very thin in comparison to Madden Pump’s robust design.

chemical metering pump, this would be the diaphragm. According to our distributors across the country, our competitors’ diaphragms are very thin in comparison to Madden Pump’s robust design.

So let’s take a look at the driving force behind the Madden chemical metering pump, and see how our diaphragms are built to last for some of the longest service life available on the market.

Tough fabric reinforced diaphragms

Our molded rubber and Nylon fabric construction diaphragms are a 1/4” thick. Tough as a tire. The molded-in diaphragm screw connects to the pump piston for the positive suction action. Service life is maximized and fatigue is minimized further by coupling all of this with a very short stroking length.

The Madden JN series pumps have a stroking length of only 0.09 inches and the MH series is only 0.38 inches. Yes, you read that right. No, they are not typos. This short stroke allows some of our diaphragms to last for 100 million cycles or more! Everything in our chemical injection pump design is intended to provide you a pump that can pump 24/7/365 with little or no down time. We want everything to be simple, rugged, and durable.

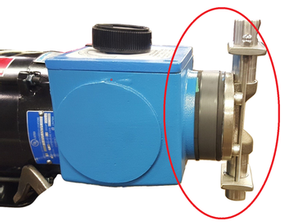

Extra Protection of a double diaphragm set up

For highly corrosive acids and caustics Madden offers even more protection and peace of mind with their Type DDB double diaphragm feature. This feature includes a backup diaphragm to keep liquid out of the pump body in the event of a leak in the primary diaphragm. Which also means it will prevent liquid from ever damaging the pump’s gearing. If a rupture occurs, the Type DDB diaphragm helps ensure that the operator can change out the primary diaphragm before any damage to the pump can occur.

Included in the spacer of the Type DDB double diaphragm set up is a 1/4” NPT connection. There is an optional MP138 leak detecting switch Madden offers which can be used to activate an alarm and/or turn off the power to the pump for automatic leak detection. Alternatively, it can be used as a weep hole or a clear tube can be installed for visual leak detection.

Conclusion

If you are in the market for a robust chemical injection pump, Madden Pump chemical metering pumps may be the last pump you ever buy. With its heavy duty design and thick rubber diaphragms, Madden metering pumps are made to be a work horse, dosing your chemicals 24/7/365 with little to no down time.

If you’d like to learn more about our metering pumps please give us a call (800-369-6233). We’d love to discuss your next applications chemical dosing needs!