!!(Author’s Note: Other than a motor malfunction, or an application flaw that causes the pump to begin to dead head, your Madden metering pump will not overheat; due to operating in an oil bath, and the bench testing every chemical injection pump at our facility for smooth, leak free operation, Madden’s robust design is made to never need repairs of any internal parts on our metering pumps. Only occasional wetted end repairs are ever required.

This article is meant to be informative, as well as to shine a light on what Madden chemical pump fabricators look for when building and testing metering pumps.)!!

Overview

Overheating can be due to a number of environmental conditions as well as mechanical issues. This article will go over the things to look for that may cause excessive heat in your metering pump and electric motor, as well as tips and tricks for getting your chemical metering pump’s operating temperature down to an optimal level.

With robust diaphragm metering pumps that include heavy metal parts throughout its design for added durability, as well as any electric motor application for that matter, overheating is a possibility. If this happens to your chemical injection pump in the field, think of it like a symptom, it is telling you something in the process has malfunctioned.

First, let’s go over what to look for and why overheating might occur

If you notice what might be high operating temperatures, the first component to check is the electric motor driving the chemical injection pump. This is where the main source of heat usually originates, heat then travels through the heavy metal parts throughout the rest of the pump.

- Check your motor’s manual. You might be surprised at how high it’s normal and max running temperatures are. Explosion proof motors without fans cooling them, for example, can operate continuously at 110-120 degrees, and sometimes even higher.

- For a standard TEFC (totally enclosed fan cooled) electric motor, check for any damage that might have occurred to the fan. Your motor could be slowly overheating as the chemical metering pump is now in service, due to poor fan circulation not drawing enough heat away from the motor.

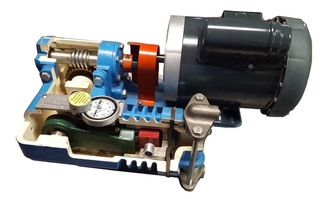

Next, begin to work your way through the pump, component by component, starting from the motor, to make sure everything is running smoothly. And by smoothly, we mean literally. Take, for example, the next part in the heavy duty Madden metering pump, the worm gear shaft and gear sprocket:

- Occasionally a worm gear and/or sprocket may have a bur on it which can cause friction and thus develop heat. Usually, these will work themselves out after a while and cease from causing a problem. As mentioned earlier, Madden chemical metering pumps are bench tested before shipping, and this particular cause of heating would therefore NOT pertain to Madden pumps in the field.

- Improper alignment of the worm gear or shaft can also cause friction. Making sure these pieces are flush will help ensure efficient operation within the metering pump. It is also important to make sure these pieces have a very slight amount of “play” in them to move around during operation. Unlike the first point, this can occasionally happen in the field, as careless shipping practices may cause the motor to misalign by the time it reaches your facility. Keep an eye out for these rare cases when receiving your positive displacement type metering pump.

Check on the operation of the drive shaft, rod, and piston that lead up to the diaphragm. All of these components should be looked over the same way the worm gear and sprocket would be.

These parts in the Madden pump are made up of cast iron, steel, and in some cases aluminum. They are very durable and rugged. If these components are not operating smoothly and are not flush with each other, this can certainly start to cause overheating due to friction.

However, again, due to Madden’s complete testing of every single pump we manufacture, before shipping, we know that the alignment of all components in a Madden metering pump have passed our standard operating requirements and will not have these issues in the field.

So what’s the main take away from noticing an overheated diaphragm metering pump?

The main point of this article is, if you notice your pump is getting hot, don’t panic, it is very likely that your chemical injection pump is fine, and it is just working harder than it should be to pump chemicals at the needed flow rate. It’s more often than not, specifically an “air locked system” which you can read more about in this article.

For industrial grade, rugged metering pumps like Madden’s, you should look at overheating as a symptom of something outside the pump. Motor failure, environmental conditions, and the beginning piping issues are all reasons your pump may be excessively working to try to continue dosing chemicals.

Check for piping failures, air locks, and motor damage first, before worrying about the metering pump. Odds are good if you are faced with an overheating chemical pump, your process line is the culprit.

Conclusion

An overheating pump is a symptom, more times than not on a rugged positive displacement pump, the heat from the pump body is the “effect” of an outside “cause”. An extremely hot pump or motor is usually a sign that it is working harder than it is designed for, and that is usually due to something in the process line.

Good news, those are usually easy fixes. Better news, unlike plastic, solenoid driven pumps, when and if this occurs in your processes line, a heavy duty pump like Madden’s will keep running after the issue is resolved. Our rugged chemical metering pumps won’t burn up or break under the stress. And at worse, it usually only needs minor wetted end replacements to get back up and running.

So if you want to avoid downtime in your chemical injection application, look into a Madden metering pump for your next purchase. Give us a call, 800-369-6233, or go straight to one of our Industrial Pump Sales Reps for more help in designing a Madden chemical metering pump for your application.

[…] What can cause a positive displacement type chemical metering pump to overheat? by Madden Pump 09/15/2017… How hot is too hot, and is it the pump itself or the application causing things to overheat? This article goes over what can happen in chemical injection applications to cause a pump to overheat. […]