We often receive calls from end users and resellers alike looking for a chemical injection pump, a transfer pump, basic metering pump, so on, but after describing their application, we realize our diaphragm metering pumps just aren’t quite what they need. Believe it or not, we aren’t aggressive, ruthless sales people here, if our pump isn’t a good fit for your application, we’ll tell you.

When diaphragm metering pumps best suit an application

When you have an application that requires you to meter liquids into other processes at a finite and accurate rate, a metering pump is well suited for this. Even more specifically, when you need that finite amount of liquid to be dosed at a consistent, repeatable rate, diaphragm metering pumps are perfect. For mechanically actuated diaphragm metering pumps, this usually means the operating pressure is less than 500 PSI, for hydraulically actuated diaphragm metering pumps the pressures can go much higher, often up to 1,000-2,000 PSI.

When it comes to these factors just mentioned, generally we’re referring to chemical treatment, or chemical addition type applications. Chemical treatment applications usually need a percentage of chemical added per ‘X’ units of the process. And the process quite often has a flow rate of its own. In a treatment process, it is important that you are dosing a specific amount of chemical, consistently. For example, if you knew you needed to add about 5 gallons of chemical to the process within an hours’ time, and that process was flowing throughout the facility, you would not want to go up to one spot and dump all 5 gallons into the process.

This is when diaphragm metering pumps are ideal. They can be set up with an injection quill, to slowly and consistently inject chemical directly into the processes. With each stroke of the diaphragm, a finite amount of chemical is dispersed into the processes line. Thereby helping to ensure even and consistent addition of said chemical to the processes.

Now, this may be the most ideal situation for diaphragm metering pumps, the case where no other pumps are going to be more efficient and better suited to get the job done per this chemical addition application; But that said, anytime you need to pump a certain amount of a liquid into a lower pressure system with great accuracy and repeatable, consistent output, a diaphragm metering pump can be considered.

Let‘s check out the why and how now.

How a Diaphragm metering pump doses with consistent and accurate output

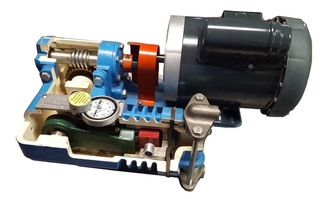

Diaphragm metering pumps offer a pulsating flow as a result of their stroking motion. The key component built into our metering pumps that allow it to produce the same amount of

Diaphragm metering pumps offer a pulsating flow as a result of their stroking motion. The key component built into our metering pumps that allow it to produce the same amount of

fluid with each and every stroke, is the check ball valve assembly.

The check ball valve assembly has a ball and seat at the inlet and outlet ends of the diaphragm pumps solution head. How they work: when you turn your pump’s electric motor on, this driving force is geared up to pull and push the diaphragm forwards and backwards with a consistent amount of strokes per minute. With each backwards stroke, the diaphragm pulls liquid into the pump’s solution head via lifting the inlet ball valve, while firmly seating the outlet ball valve down to ensure no liquid leaves the solution head or enters back in from the discharge line. When the diaphragm then reverses course and surges forward, this drives the liquid out of the solution head, lifting the outlet ball, while firmly pushing the inlet ball back down to be seated, creating a seal that does not allow the liquid in the solution head to go back to the suction line, or for any chemical in the suction line to enter the solution head.

Thereby ensuring each and every stroke of the pump, at a certain speed, against a certain pressure, will produce the same amount of liquid chemical each and every time it does so.

Why a diaphragm metering pump is best for your application

The “why” is pretty straight forward because in our opinion, when diaphragm metering pumps are best, the reasons can be boiled down to two simple reasons: cost and safety.

When dosing chemicals into a process, cost of the chemical is usually of much more concern then paying for the equipment to do so. Your diaphragm chemical metering pump may cost you as much as $1,500 to $5,000 not including other components you need to complete a full dosing system, but that pales in comparison to the amount of money the application calls for in recurring chemical costs. Chemical addition applications are usually treating something, which is done because it is necessary/required by law, or it is being added to something to create a product, which you sell. Point being, chemical addition applications are very cost oriented processes, a durable, and accurate pump is what you need, and why specifically a diaphragm metering pump is great for these applications.

And then there is safety. Often times the chemicals we are pumping are dangerous when coming in contact with a person or the environment. You don’t want to over dose or under dose the processes you are adding the chemical to, as over treating or under treating may cause the process to become dangerous or vice versa. You also do not want your pump to corrode and start allowing the chemical to leak out of the process line and into the surrounding environment. Accurate diaphragm metering pumps are a great solution to both of these concerns. You can choose from many different materials to make the pumps wetted end as durable as possible, as resistant to the chemical as possible, and you can be assured, as we went over earlier, that these types of pumps will dose consistently and accurately. Rest assured diaphragm metering pumps won’t over or under dose in your system unless there is operator error or an uncaught failure somewhere in the pump or process line.

Application examples of where diaphragm metering pumps are often found

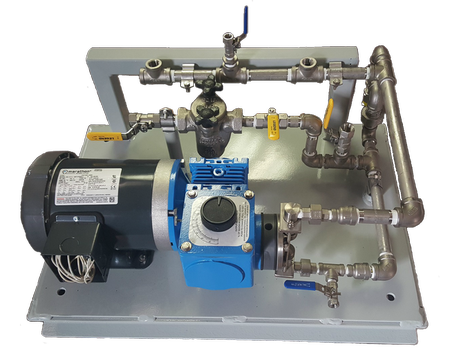

|

|

| Madden JN series dosing skid, blank slate, many ancillary equipment options available |

Diaphragm metering pumps are found all over industrial applications, but water treatment would be one of the more common, specific applications where this kind of chemical addition is important. Some of the applications you will find Madden diaphragm metering pumps in are as follows:

- PH balancing: most often we are talking about adding an acid like Sulfuric Acid to a water stream or a base like Caustic soda, to reach a neutral PH level, or otherwise desired level.

- Boiler water treatment: usually in boiler water treatment 3 common chemical additives are desired to be put into the water, an oxygen scavenger, a phosphate, and an amine or ammonia. These chemicals slowly dosed into the boilers feed water help the boiler operate more efficiently. Cleaner water equates to more efficient steam production.

- Coagulation or Flocculation applications. Coagulation and flocculation are similar water treatment applications where the goal is to bind impurities in the water for easier removal. Madden has made a design specifically for pumping thicker polymers, with spring loaded valve assemblies to help maintain consistent, repeatable, accurate output.

And obviously, there are many more applications. Hopefully now having read this article and understanding where diaphragm metering pumps work best, you might know of or have other applications where you think these metering pumps would excel as well.

Conclusion

If you have an application requiring a consistent and accurate flow rate, consider a Madden diaphragm metering pump. Call the factory or get in touch with one of our sales reps to discuss your application. Our team would be happy to discuss all of the options you have and the ancillary equipment you may need to add to your chemical injection pump.

[…] Understanding when it’s best to use a Diaphragm metering pump vs. other chemical pumps by Madden P… 05/11/2018… Pumping chemicals is costly, and the research that goes into procuring a chemical injection system is costly and time consuming as well. This article will help inform you of when diaphragm metering pumps are your best choice. […]