Sodium hydroxide, often called caustic soda or lye, is a common chemical handled by Madden metering pumps. With corrosive substances like sodium hydroxide, it is important to find a chemical metering pump with materials available that can come into contact with this chemical, and last for a considerable amount of time. Any leaks or damage that occur in a pump which is processing a chemical like this could have disastrous consequences to the things surrounding it.

At Madden we take pride in our pumps’ ability to handle such a corrosive chemical; knowing that Madden metering pumps are set up with the best wetted end materials available should give the end user peace of mind while pumping Sodium Hydroxide.

Sodium Hydroxide, what exactly is it?

At room temperature sodium hydroxide is a white crystalline odorless solid that absorbs moisture from the air. It is a very corrosive substance, especially to metals and tissue. Sodium hydroxide is not organic, it is a manufactured substance that when dissolved or neutralized with acid, gives off substantial heat, which can be sufficient to ignite combustible materials.

Sodium hydroxide is generally used as a solid or as a 50% solution. It is used to manufacture soaps, rayon, paper, explosives, dyestuffs, and petroleum products. It is also used in processing cotton fabric, laundering and bleaching, metal cleaning and processing, oxide coating, electroplating, and electrolytic extracting. (Information gathered from PubChem, National Center for Biotechnology Information: link)

However, more often than not, we see it used to simply treat acidic water. There are many reasons a company may need to treat water, and if yours is one of them, Madden certainly has an accurate, durable metering pump for your consideration.

How Madden Pumps are set up to handle Caustic Sodas

First and foremost, there is no pump out there that can handle these corrosive chemicals forever. Eventually parts are going to wear out (for Madden pumps that can be 10+ years down the road).

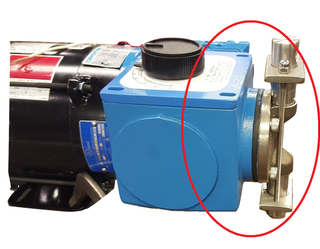

Madden Pump recognizes this, and that is why all of our industrial diaphragm metering pumps have a DDB double diaphragm option for further safety.

|

|

| Standard, Single diaphragm on a JN pump | DDB double diaphragm on a JN pump |

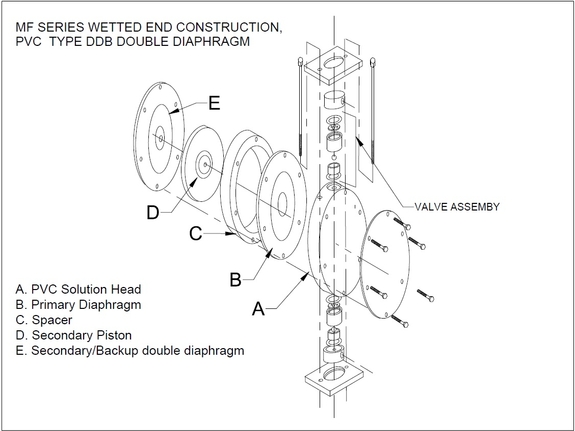

The DDB design adds a spacer and another, backup/secondary diaphragm to the chemical pump’s wetted end to ensure the corrosive chemical, like caustic soda, never reaches inside and damages the pump’s interior components. This is one big reason why when properly maintained, there are Madden metering pumps out there that have lasted for over 25 years with only minor wetted end parts replacements.

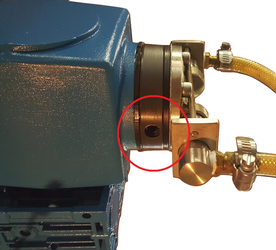

The other great feature with the DDB double diaphragm is the ability to place a pressure switch in the spacer between diaphragms. There is a 1/4” NPT hole in the spacer that allows for a pressure switch to be installed. The pressure switch should be set to the lowest level. Under normal operating conditions the pressure inside this spacer is the same as the ambient air surrounding it. So if the pressure switch is set to its lowest setting and there is any kind of rupture in the pump’s diaphragm, the smallest amount of pressure that results will set off the pressure switch. From there you can either wire it to an alarm or wire it to shut of the motor; making absolutely certain harsh chemicals like sodium hydroxide will never touch the shop floor or anything else near the pump.

The other great feature with the DDB double diaphragm is the ability to place a pressure switch in the spacer between diaphragms. There is a 1/4” NPT hole in the spacer that allows for a pressure switch to be installed. The pressure switch should be set to the lowest level. Under normal operating conditions the pressure inside this spacer is the same as the ambient air surrounding it. So if the pressure switch is set to its lowest setting and there is any kind of rupture in the pump’s diaphragm, the smallest amount of pressure that results will set off the pressure switch. From there you can either wire it to an alarm or wire it to shut of the motor; making absolutely certain harsh chemicals like sodium hydroxide will never touch the shop floor or anything else near the pump.

Choosing the right wetted end materials to handle Caustic Soda

It can vary slightly depending on the end user’s personal experience and preference, as well as being dependent on the model of Madden pump you need, but usually the wetted end materials for a chemical metering pump needing to pump caustic soda is as follows:

- Solution Head: PVC or 316 Stainless Steel

- Primary Diaphragm: Teflon or Hypalon

- Valve Seats: Teflon or Hypalon

- Valve Balls: Teflon or 316 Stainless Steel

- DDB double diaphragm: Hypalon

Conclusion

If you have an application requiring dangerous or corrosive chemicals like sodium hydroxide to be pumped, Madden has a pump for your consideration.

|

|

|

| JN series metering pump | MF series metering pump | MH series metering pump |