When an application calls for the pumping of thick, viscous liquids, Madden has a valve assembly designed to handle these slurries and polymers which can have viscosities as high as 450 cPs. The design can pump these liquids without losing output or accuracy.

How is this done?

By adding springs to our check ball valve system. These springs ensure that the check balls will seat firmly and consistently on the valve seat, to maintain accuracy and produce consistent output while metering your thicker chemical, slurry, or polymer.

Understanding a standard Madden Valve Assembly

Under normal operating conditions, operating pressure and gravity are what allow the balls in the valve assembly to seat firmly and consistently. Madden uses check ball valves in their metering pumps. When the pump is stroking backwards, the diaphragm draws liquid into the suction side and the bottom check ball floats up to allow the liquid to pass through. At the same time, the backwards draw of the diaphragm, along with gravity and operating pressure, presses the top ball down firmly on its valve seat. The opposite happens during a forward stroke of the diaphragm.

This repeating action of the bottom and top check ball valves seating and unseating is a very important feature allowing for true metering, or dosing, of a chemical. A positive displacement metering pump will have a stroke length that can be adjusted. No matter what the length of the stroke is set to, properly functioning check ball valves are the finishing feature to ensure that with every single stroke, your dosing pump is pumping the same amount it did the stroke before, within +/- 1%.

So, what happens when we’re pumping thicker, viscous liquids with a Madden metering pump and the check balls don’t want to seat properly?….

Spring Loaded Valve Assembly

If you were to take a Madden pump and begin to pump a polymer, for example, with a viscosity of about 150-200 cPs, the polymer would be pumped but you would start to notice inconsistencies in output. So what are the “real life” implications?

Normally, Polymers are used as coagulants for flocculation in waste water treatment. So, as you are dosing the Polymer into your waste water, without a special design to deal with the viscous polymer, the loss of consistency and accuracy could lead to under treated waste water. Under treating your waste water could keep flocculants from forming, thus potential bacteria remaining in the water.

So, in theory, if you were simply using a Madden metering pump as a transferring pump, it would function as such, a pump to transfer liquid from one place to another. However, what sets our spring loaded valve pumps apart, is that this design allows our pumps to still remain a true metering or dosing pump, even when the liquids are viscous. Madden chemical pumps can maintain accuracy and consistency in your pumping applications at viscosities as high as 450 cPs by using our spring loaded check valve design:

Take a look:

| Standard Valve Assembly | Spring Loaded Valve Assembly |

|

|

| Standard valve assembly put together |

|

| Spring loaded valve assembly layout |

|

| Spring loaded valve partially assembled |

|

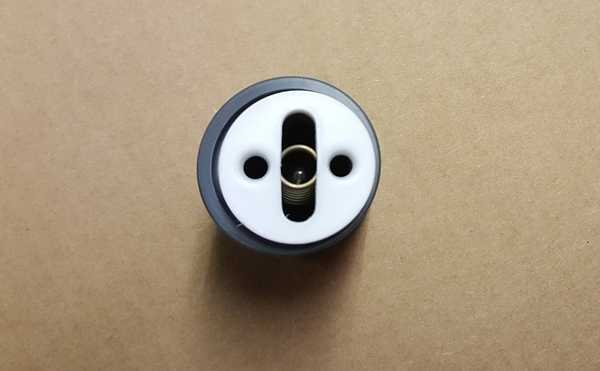

| Assembled spring loaded valve |

|